1. The present utility model relates to the technical field of moulds, specifically a plastic cup mould assembly and mould.

Background technology.

2. Mold, industrial production used for injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods to get the desired product of a variety of molds and tools, in short, the mold is used to make molding items, this tool consists of a variety of parts, different mold consists of different parts, it is mainly through the physical state of the material being molded to achieve the processing of the shape of the item, and in In the process of processing, there are many problems or defects in the existing

plastic cup mold components and molds.

3. In actual use, the traditional plastic cup mold components and molds are generally injected into the mold cavity by injection molding machine at high pressure for cooling and curing, but the cooling time in this way is too long to get finished products quickly, resulting in low injection effect of the mold, and at the same time the water after cooling is directly discharged without treatment, which is not conducive to the sustainable development of resources.

Technical realization elements.

4. The purpose of the present utility model is to provide a plastic cup mold assembly and mold to solve the problems raised in the above-mentioned background technology.

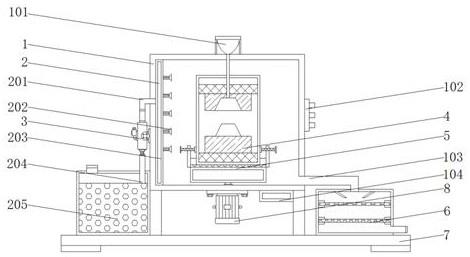

5. In order to achieve the above-mentioned purpose, the utility model provides the following technical solution: a plastic cup mold assembly and mold, including a base, said top of the base is fixedly installed with a box, said bottom of the box is fixedly installed with a motor, said output end of the motor is fixedly installed with a transmission assembly, said top of the transmission assembly is movably installed with a mold body, said side of the box is fixedly installed with a spraying assembly, said The spraying component is fixedly installed between the suction pump, the other side of the box body is fixedly installed with a filtering component.

6. As a further solution of the utility model: the spraying assembly includes a water tank, the top of the water tank is fixed with a water inlet pipe, the top of the water inlet pipe is fixed with a water guide pipe, the other side of the water guide pipe is fixed with a water storage pipe, the other side of the water storage pipe is equidistantly installed with atomization nozzle.

7. As a further solution of the utility model: the filter assembly includes a filter box, the top of the filter box is fixed with a guide plate, the bottom of the guide plate is set with a first filter, the bottom of the first filter is set with a second filter, the two ends of the first filter and the second filter are fixed with a limit block, the bottom of the limit block is fixed with an outlet pipe.

Latest blog posts

Custom molds injection molding

Custom molds injection molding is a manufacturing process that involves creating custom molds to produce plastic parts. Injection molding is a popular technique used in various industries such as...

Plastic injection molding companies

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold to create a wide range of plastic products. From car parts to medical devices and household items, plastic injection molding is used to create a variet

PET Preform Injection Moulding Machine

PET preform injection molding is a manufacturing process that is used to create PET (polyethylene terephthalate) preforms that can be later blown into bottles, jars, and other containers. This process...

You may like

Two-colour injection moulding process

The two-colour injection moulding process is a process whereby two different plastics are moulded into one set of moulds to form two materials or colours into one plastic part at the same time...

Injection molding machine maintenance of common failure problems and solutions?

Injection molding machine in improper operation or improper use will also occur when a lot of failure problems, really in understanding the injection molding machine repair should have...

How to increase the brightness of injection molded products from process and mold?

I. Injection mold, 1). If the mold cavity processing is poor, such as scars, microporous, wear, roughness, and other deficiencies, will inevitably react to the plastic parts...

How to solve the problem of burned injection molded parts?

Injection molds often produce burns for some reason during production. Depending on the burn caused by different reasons such as mechanical, mold, or molding conditions, different solutions are taken...